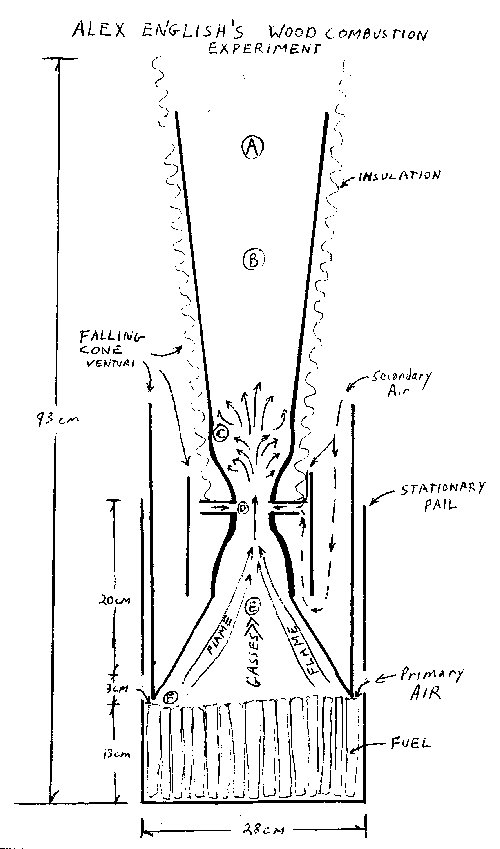

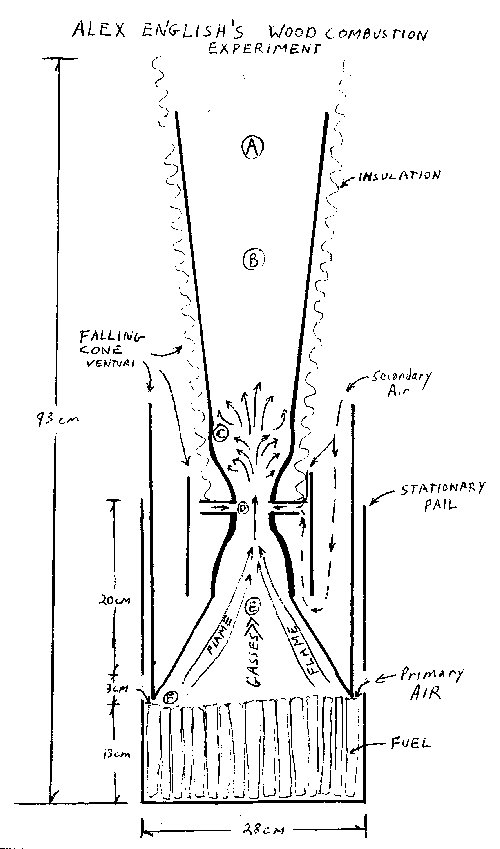

Drawing and discription of the venturi burner..

The diagram above shows my attempt to optimize the combustion of the gasses, using natural draft, from pyrolising wood which is ignited on the top and pyrolises from the top down. This top down gasification of the fuel seem to produce a more consistent output than "bottom lit" fires.

The venturi (point D), with its tangential air supply, sets up a vigorous turbulence in the region of point C. During start up the flame is less turbulent and and extends to point B. The fire appears to builds in strength until a balance is reached between the various gas flow rates. The flame at point C becomes more turbulent and 'cleaner' ( with allot of blue ) and only occasional excursions to point B.

The flame below the cone extends from high points in the fuel and points where the cone rests on the fuel supply. The fuel around the outside where the cone rests is consumed slowly during the burn causing the cone/venturi to drop until it eventually rests on the bottom of the pail. This is about the time that the wood in the centre stops pyrolising and begins to burn as charcoal. The cone sitting on the fuel as it burns maintains a fairly consistent fuel/gas/flow dynamic.

Measurements were taken at point A. This arrangement has yielded a fairly steady output based on the appearance of the flame. CO appears to be low ( below 100ppm) beginning with the development of a turbulent flame and until the fuel has exhausted its volatile component. The smoke test remains high longer than CO but declines through the burn. CO2 stays within the 10-16% range.

This experiment has proved to my satisfaction that fairly stable high C02 to CO ratios are possible without using the downdraft configuration.

Check the following pictures. Picture 1 shows the venturi arrangement before the swirl inducing ring, pictures 2 3 , was added.