|

Our Technology |

|

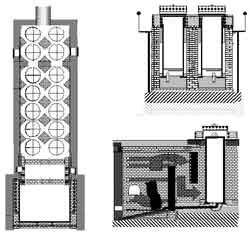

Ekolon Plan and Sections |

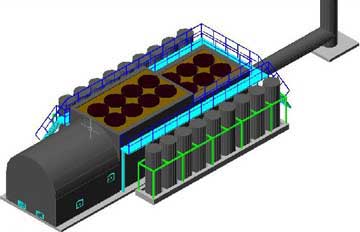

Ekolon General View |

The base principle of operation for all of our units is as follows. Firewood is placed into vertical removable retorts and then inserted in the kiln. The retorts have a special device at the bottom to extract a steam and gas mixture to the furnace. The gas and liquid wood decomposition products are completely burned in the furnace to produce heat for the unit operation. Therefore, there are no harmful emissions that could pollute the air. The steam and gas mixture is burned. The heat flows through the sections for pyrolysis and drying, heats them and is extracted into the smoke-stack. The flue gas content is similar to that of the domestic wood stove. NOx and CO content in the flue gas is much lower than the maximum allowable concentration.

There are no fans or pressure-blowing device in the facility design. The process of producing charcoal goes on due to natural draft from the smoke-stack. There is no other power consumption except the lightning, mechanical wood-chopper and hoisting equipment - a telpher or crane with 3-5 ton lifting capacity.

Besides the furnace and hoisting equipment the charcoal facility includes a charcoal storage with a packing room, a loader, a wood handling room with a saw and a wood-chopper, retort racks, retort loaders, a staff cabin and operators staff room. The space needed for all parts of the facility including the raw material exchange and storage is 30x55m2.

|

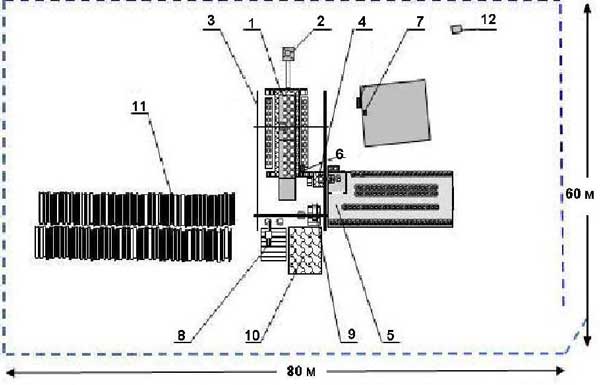

Ekolon Layout |

| 1. Ekolon Board 2. Draft Stack 3. Crane Platform 4. Remove, Sort and Package Charcoal 5. Warehouse, storeroom 6. Equipment room |

7. Equipment Room 8. Raw Material Processing 9. Retort Platform 10. Firewood Storage 11. Lumber Storage 12. Electrical Service |